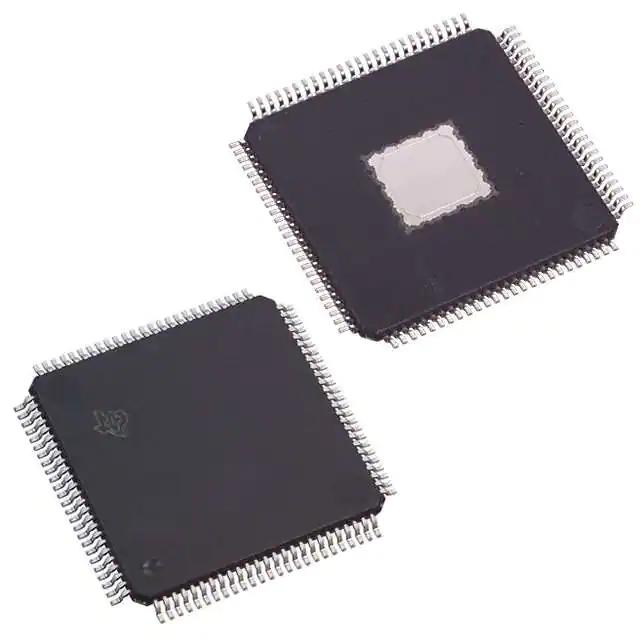

Chitsva chitsva chechokwadi chepakutanga IC stock Yemagetsi Zvikamu Ic Chip Tsigiro BOM Service DS90UB953TRHBRQ1

Product Attributes

| TYPE | DESCRIPTION |

| Category | Integrated Circuits (ICs) |

| Mfr | Texas Instruments |

| Series | Motokari, AEC-Q100 |

| Package | Tepi & Reel (TR) Cheka Tape (CT) Digi-Reel® |

| SPQ | 3000T&R |

| Product Status | Active |

| Basa | Vadivelu Comedy Serializer |

| Data Rate | 4.16Gbps |

| Input Type | CSI-2, MIPI |

| Output Type | FPD-Link III, LVDS |

| Nhamba Yezvakaiswa | 1 |

| Nhamba Yezvinobuda | 1 |

| Voltage - Supply | 1.71V ~ 1.89V |

| Operating Temperature | -40°C ~ 105°C |

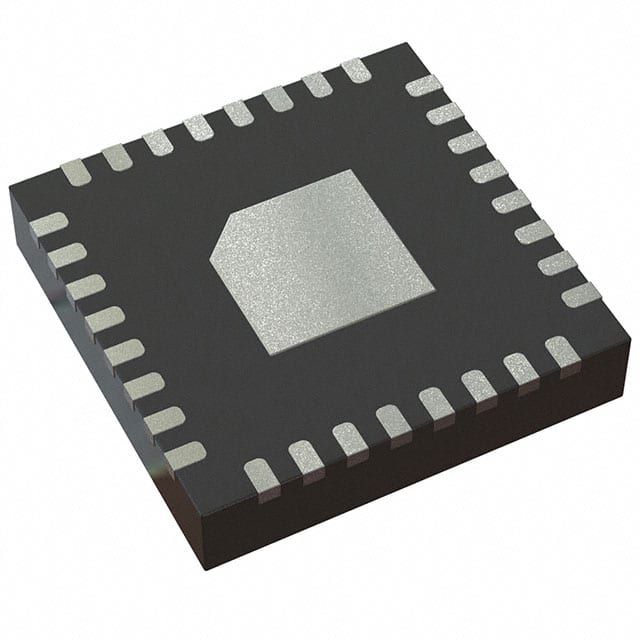

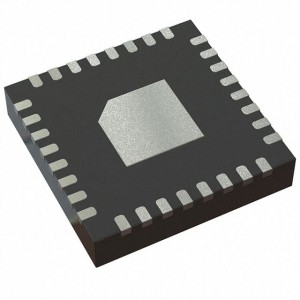

| Mounting Type | Surface Mount, Wettable Flank |

| Package / Nyaya | 32-VFQFN Yakafumurwa Pad |

| Supplier Device Package | 32-VQFN (5x5) |

| Base Product Number | DS90UB953 |

1.Sei nesilicon kuti machipisi?Pane here zvinhu zvinogona kuitsiva mune ramangwana?

Iyo mbishi yemachipisi mawafer, ayo anoumbwa nesilicon.Pane fungidziro isiriyo yekuti "jecha rinogona kushandiswa kugadzira machipisi", asi izvi handizvo.Icho chikuru chemakemikari chikamu chejecha silicon dioxide, uye chikuru chemakemikari chikamu chegirazi uye wafers zvakare silicon dioxide.Musiyano, zvisinei, ndewekuti girazi ipolycrystalline silicon, uye jecha rinopisa pakupisa kwakanyanya rinoburitsa polycrystalline silicon.Wafers, kune rumwe rutivi, ari monocrystalline silicon, uye kana akagadzirwa kubva mujecha anofanirwa kushandurwa zvakare kubva ku polycrystalline silicon kuenda kumonocrystalline silicon.

Chii chaizvo chinonzi silicon uye nei chichigona kushandiswa kugadzira machipisi, isu ticharatidza izvi mune ino chinyorwa chimwe nechimwe.

Chinhu chekutanga chatinofanira kunzwisisa ndechekuti silicon zvinhu haisi kusvetuka zvakananga kune chip nhanho, silicon inonatswa kubva kujecha requartz kunze kweiyo element silicon, silicon element proton nhamba kupfuura element element aluminium imwezve, pane iyo element phosphorus imwe zvishoma. , hausi chete hwaro hwezvinhu zvemichina yemazuva ano yemakomputa asiwo vanhu vari kutsvaga hupenyu hwekunze kwepasi chimwe chezvinhu zvakakosha zvinogoneka.Kazhinji, kana silicon yacheneswa uye kucheneswa (99.999%), inogona kugadzirwa kuita silicon wafers, iyo inobva yachekwa kuita wafers.Iyo yakatetepa chidimbu, inodzikira mutengo wekugadzira chip, asi inokwirisa zvinodikanwa zveiyo chip process.

Matanho matatu akakosha ekushandura silicon kuita mawafers

Kunyanya, shanduko yesilicon kuita mawafer inogona kukamurwa kuita matanho matatu: silicon kunatsa uye kucheneswa, imwe chete crystal silicon kukura, uye wafer kuumba.

Muzvisikwa, silicon inowanzowanikwa muchimiro chesilicate kana silicon dioxide mujecha nematombo.Iyo mbishi inoiswa muchoto chemagetsi arc pa2000 ° C uye pamberi pekabhoni sosi, uye tembiricha yepamusoro inoshandiswa kuita silicon dioxide nekabhoni (SiO2 + 2C = Si + 2CO) kuwana metallurgical giredhi silicon. kuchena kwakapoteredza 98%).Zvisinei, kuchena uku hakuna kukwana pakugadzirira kwezvikamu zvemagetsi, saka inofanira kucheneswa zvakare.Iyo yakapwanyika metallurgical giredhi silicon inonatswa negaseous hydrogen chloride kugadzira mvura silane, iyo inozonyungudutswa uye nemakemikari inoderedzwa nemaitiro anoburitsa kuchena kwepamusoro polysilicon nekuchena kwe99.999999999% sesilicon yegiredhi remagetsi.

Saka iwe unowana sei monocrystalline silicon kubva ku polycrystalline silicon?Nzira yakajairika ndiyo nzira yekudhonza yakananga, apo polysilicon inoiswa mu quartz crucible uye inopisa nekushisa kwe 1400 ° C inobatwa pamucheto, iyo inogadzira polysilicon inyauka.Ehezve, izvi zvinotungamirwa nekunyudza mhodzi yekristaro mukati mayo uye kuita kuti tsvimbo yekudhirowa itakure mhodzi yekristaro kune yakatarisana uku ichikwevera zvishoma nezvishoma ichikwira kumusoro kubva kusilicon kunyungudika.Iyo polycrystalline silicon inonyunguduka inonamira kuzasi kwekristaro yembeu uye inokura ichikwira kumusoro kwakanangana nemhodzi yekristaro lattice, iyo mushure mekudzurwa kunze uye kutonhodzwa inokura kuita bhara rekristaro rine kutaridzika kwakafanana kwekrisiti yemhodzi yemukati.Chekupedzisira, zvimedu zvekristaro zvimwechete zvinodonhedzwa, kutemwa, pasi, kupepereswa, uye kukwenenzverwa kuti zvibudise zvakakosha-zvese.

Zvichienderana nehukuru hwakachekwa, zvimedu zvesilicon zvinogona kuiswa se6 ", 8", 12 "uye 18".Iyo yakakura saizi yewafer, iyo machipisi akawanda anogona kutemwa kubva kune yega yega wafer, uye yakaderera mutengo pane chip.

2.Matanho matatu akakosha mukushandurwa kwesilicon kuita mawafers

Kunyanya, shanduko yesilicon kuita mawafer inogona kukamurwa kuita matanho matatu: silicon kunatsa uye kucheneswa, imwe chete crystal silicon kukura, uye wafer kuumba.

Muzvisikwa, silicon inowanzowanikwa muchimiro chesilicate kana silicon dioxide mujecha nematombo.Iyo mbishi inoiswa muchoto chemagetsi arc pa2000 ° C uye pamberi pekabhoni sosi, uye tembiricha yepamusoro inoshandiswa kuita silicon dioxide nekabhoni (SiO2 + 2C = Si + 2CO) kuwana metallurgical giredhi silicon. kuchena anenge 98%).Zvisinei, kuchena uku hakuna kukwana pakugadzirira kwezvikamu zvemagetsi, saka inofanira kucheneswa zvakare.Iyo yakapwanyika metallurgical giredhi silicon inonatswa negaseous hydrogen chloride kugadzira mvura silane, iyo inozonyungudutswa uye nemakemikari inoderedzwa nemaitiro anoburitsa kuchena kwepamusoro polysilicon nekuchena kwe99.999999999% sesilicon yegiredhi remagetsi.

Saka iwe unowana sei monocrystalline silicon kubva ku polycrystalline silicon?Nzira yakajairika ndiyo nzira yekudhonza yakananga, apo polysilicon inoiswa mu quartz crucible uye inopisa nekushisa kwe 1400 ° C inobatwa pamucheto, iyo inogadzira polysilicon inyauka.Ehezve, izvi zvinotungamirwa nekunyudza mhodzi yekristaro mukati mayo uye kuita kuti tsvimbo yekudhirowa itakure mhodzi yekristaro kune yakatarisana uku ichikwevera zvishoma nezvishoma ichikwira kumusoro kubva kusilicon kunyungudika.Iyo polycrystalline silicon inonyunguduka inonamira kuzasi kwekristaro yembeu uye inokura ichikwira kumusoro kwakanangana nemhodzi yekristaro lattice, iyo mushure mekudzurwa kunze uye kutonhodzwa inokura kuita bhara rekristaro rine kutaridzika kwakafanana kwekrisiti yemhodzi yemukati.Chekupedzisira, zvimedu zvekristaro zvimwechete zvinodonhedzwa, kutemwa, pasi, kupepereswa, uye kukwenenzverwa kuti zvibudise zvakakosha-zvese.

Zvichienderana nehukuru hwakachekwa, zvimedu zvesilicon zvinogona kuiswa se6 ", 8", 12 "uye 18".Iyo yakakura saizi yewafer, iyo machipisi akawanda anogona kutemwa kubva kune yega yega wafer, uye yakaderera mutengo pane chip.

Nei silicon iri iyo yakanyanya kukodzera zvinhu kugadzira machipisi?

Nechepfungwa, ese semiconductors anogona kushandiswa se chip zvinhu, asi zvikonzero zvikuru nei silicon ndiyo yakanyanya kukodzera zvinhu kugadzira machipisi ndeaya anotevera.

1, maererano nechiyero chepasi chekutanga chemukati, mukurongeka: okisijeni > silicon > aluminium > iron > calcium > sodium > potassium ...... inogona kuona kuti silicon iri panzvimbo yechipiri, zviri mukati zvakakura, izvo zvinobvumirawo chip kuti ive nehuwandu husingapere hwezvinhu zvekushandisa.

2, silicon chinhu chemakemikari zvimiro uye zvinhu zvemukati zvakagadzikana zvakanyanya, yekutanga transistor kushandiswa kwesemiconductor zvinhu germanium kugadzira, asi nekuti tembiricha inodarika 75 ℃, iyo conductivity ichave shanduko huru, inoitwa muPN junction mushure mekudzokera kumashure. kuvuza ikozvino kwegermanium kupfuura silicon, saka kusarudzwa kwesilicon element sechinhu chechip kunonyanya kukodzera;

3, silicon element yekuchenesa tekinoroji yakakura, uye yakaderera mutengo, mazuvano kucheneswa kwesilicon kunogona kusvika 99.9999999999%.

4, silicon zvinhu pachayo haina-chepfu uye haina kukuvadza, chiri zvakare chimwe chezvikonzero zvakakosha nei ichisarudzwa sechinhu chekugadzira machipisi.

.png)