Zvemagetsi Zvikamu IC Chips Akabatanidzwa Masekete IC TPS74701QDRCRQ1 imwe nzvimbo tenga

Product Attributes

| TYPE | DESCRIPTION |

| Category | Integrated Circuits (ICs) |

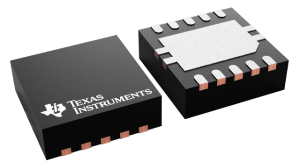

| Mfr | Texas Instruments |

| Series | Motokari, AEC-Q100 |

| Package | Tepi & Reel (TR) Cheka Tape (CT) Digi-Reel® |

| Product Status | Active |

| Output Configuration | Positive |

| Output Type | Adjustable |

| Nhamba yeVatongi | 1 |

| Voltage - Input (Max) | 5.5V |

| Voltage - Kubuda (Mini/Yakagadziriswa) | 0.8V |

| Voltage - Kubuda (Max) | 3.6V |

| Voltage Dropout (Max) | 1.39V @ 500mA |

| Zvazvino - Output | 500mA |

| PSRR | 60dB ~ 30dB (1kHz ~ 300kHz) |

| Kudzora Zvinhu | Gonesa, Simba Yakanaka, Yakapfava Kutanga |

| Dziviriro Features | Pamusoro Pazvino, Pamusoro peTembiricha, Yepfupi Circuit, Pasi peVoltage Lockout (UVLO) |

| Operating Temperature | -40°C ~ 125°C |

| Mounting Type | Surface Mount |

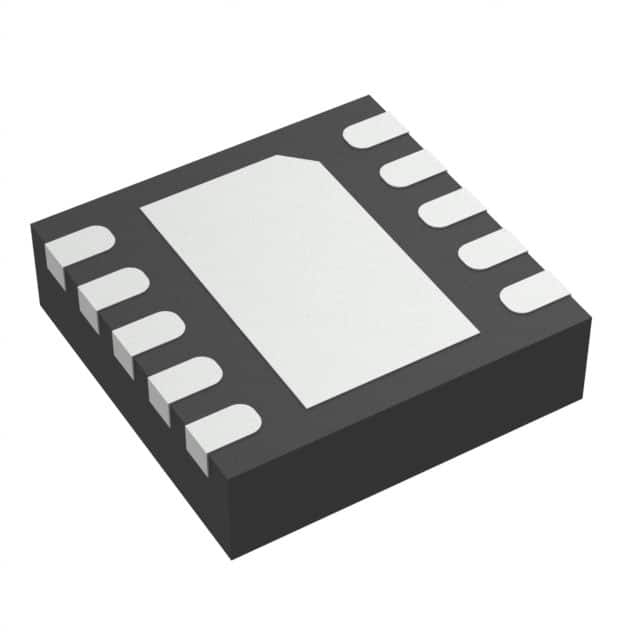

| Package / Nyaya | 10-VFDFN Yakafumurwa Pad |

| Supplier Device Package | 10-VSON (3x3) |

| Base Product Number | TPS74701 |

Hukama pakati pewafers nemachipisi

Mhedziso yewafers

Kuti unzwisise hukama pakati pewafers nemachipisi, zvinotevera tarisiro yezvinhu zvakakosha zvewafer uye chip ruzivo.

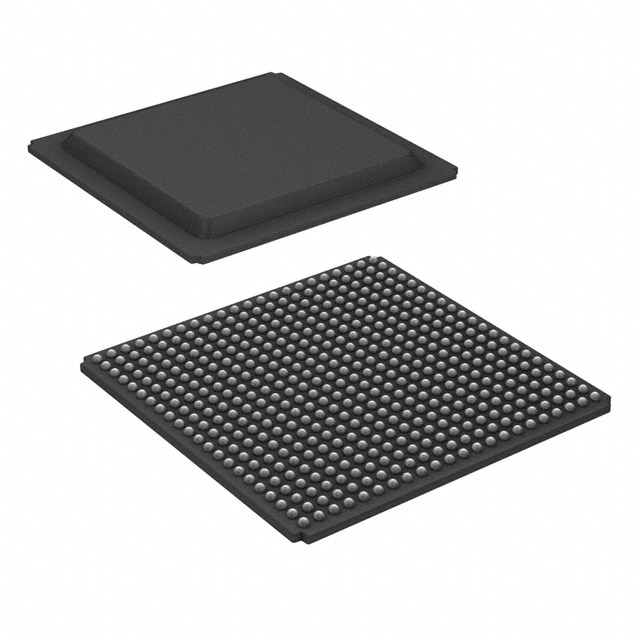

(i) Chii chinonzi wafer

Mawafers masilicon wafers anoshandiswa mukugadzirwa kwesilicon semiconductor integrated circuits, anonzi mawafer nekuda kwechimiro chawo chedenderedzwa;zvinogona kugadziriswa pasilicon wafers kuumba zvakasiyana-siyana zvedunhu zvikamu uye kuva zvakabatanidzwa zvedunhu zvigadzirwa zvine chaiwo mabasa emagetsi.Iyo mbishi yemawaferi isilicon, uye pane isingapere simbi yesilicon dioxide pamusoro pevhu.Silicon dioxide ore inonatswa mumagetsi arc furnaces, chlorinated nehydrochloric acid uye yakanyungudutswa kuti ibudise yakakwira kuchena polysilicon nekuchena kwe99.99999999999%.

(ii) Basic mbishi zvinhu zvewafers

Silicon inonatswa kubva kujecha requartz uye mawaferi anocheneswa (99.999%) kubva kune element silicon, iyo inozoitwa kuita silicon tsvimbo inova iyo yezvinhu zvequartz semiconductors yemasekete akabatanidzwa.

(iii) Wafer kugadzira maitiro

Wafers ndiyo yakakosha zvinhu zvekugadzira semiconductor machipisi.Iyo inonyanya kukosha mbishi ye semiconductor yakasanganiswa maseketi isilicon uye saka inoenderana nesilicon wafers.

Silicon inowanikwa zvakanyanya mune zvakasikwa muchimiro chesilicates kana silicon dioxide mumatombo nematombo.Kugadzirwa kwesilicon wafers kunogona kupfupikiswa mumatanho matatu ekutanga: silicon kunatsa uye kucheneswa, imwe crystal silicon kukura, uye wafer kugadzira.

Yekutanga ndeyekucheneswa kwesilicon, uko iyo mbishi yejecha nematombo inoiswa muchoto chemagetsi arc patembiricha ingangoita 2000 ° C uye pamberi pekabhoni sosi.Pakupisa kwakanyanya, iyo kabhoni nesilicon dioxide mujecha nematombo inosangana nemakemikari reaction (kabhoni inosanganiswa neokisijeni, ichisiya silicon) kuti iwane silicon yakachena nekuchena kunosvika 98%, inozivikanwawo semetallurgical giredhi silicon, iyo isiri iyo. kwakachena zvakakwana kune microelectronic madivayiri nekuti iwo emagetsi zvimiro zve semiconductor zvinhu zvinonyanya kutarisisa kuunganidzwa kwetsvina.Metallurgical giredhi silicon inocheneswa zvakare: iyo yakapwanyika metallurgical giredhi silicon inoiswa kune chlorination reaction ine gaseous hydrogen chloride kuti ibudise silane yemvura, iyo inobva yanyungudutswa uye nemakemikari yakaderedzwa nemaitiro anoburitsa yakakwirira-kuchena polycrystalline silicon nekuchena kwe99.999999999999999999999999999999999 %, inova yemagetsi giredhi silicon.

Inotevera inouya monocrystalline silicon kukura, iyo inonyanya kuzivikanwa nzira inonzi yakananga kudhonza (CZ nzira).Sezvinoratidzwa mumufananidzo uri pasi apa, high-purity polysilicon inoiswa mu quartz crucible uye inopisa nguva dzose ne graphite heater yakakomberedza kunze, kuchengetedza tembiricha inenge 1400 ° C.Iyo gasi muchoto inowanzoita inert, ichibvumira iyo polysilicon kunyunguduka pasina kugadzira kusingadiwi kemikari.Kugadzira makristasi ega, kutaridzika kwemakristasi kunodzorwawo: iyo crucible inotenderedzwa ne polysilicon yakanyunguduka, kristaro yembeu inonyudzwa mukati mayo, uye tsvimbo yekudhirowa inotakurwa kune yakatarisana nepo ichikwevera zvishoma nezvishoma kumusoro kubva kumusoro. silicon inyauka.Iyo polysilicon yakanyungudutswa inonamira pasi pemhodzi yekristaro uye inokura ichikwira kumusoro kwakanangana nelatisi gadziriro yemhodzi yekristaro.